1.61 MR-8 Blue Cut Single Vision HMC Optical lenses

Production Details

| Place of Origin: | Jiangsu | Brand Name: | BORIS |

| Model Number: | High Index Lens | Lenses Material: | Mr-8 |

| Vision Effect: | Blue Cut | Coating Film: | HC/HMC/SHMC |

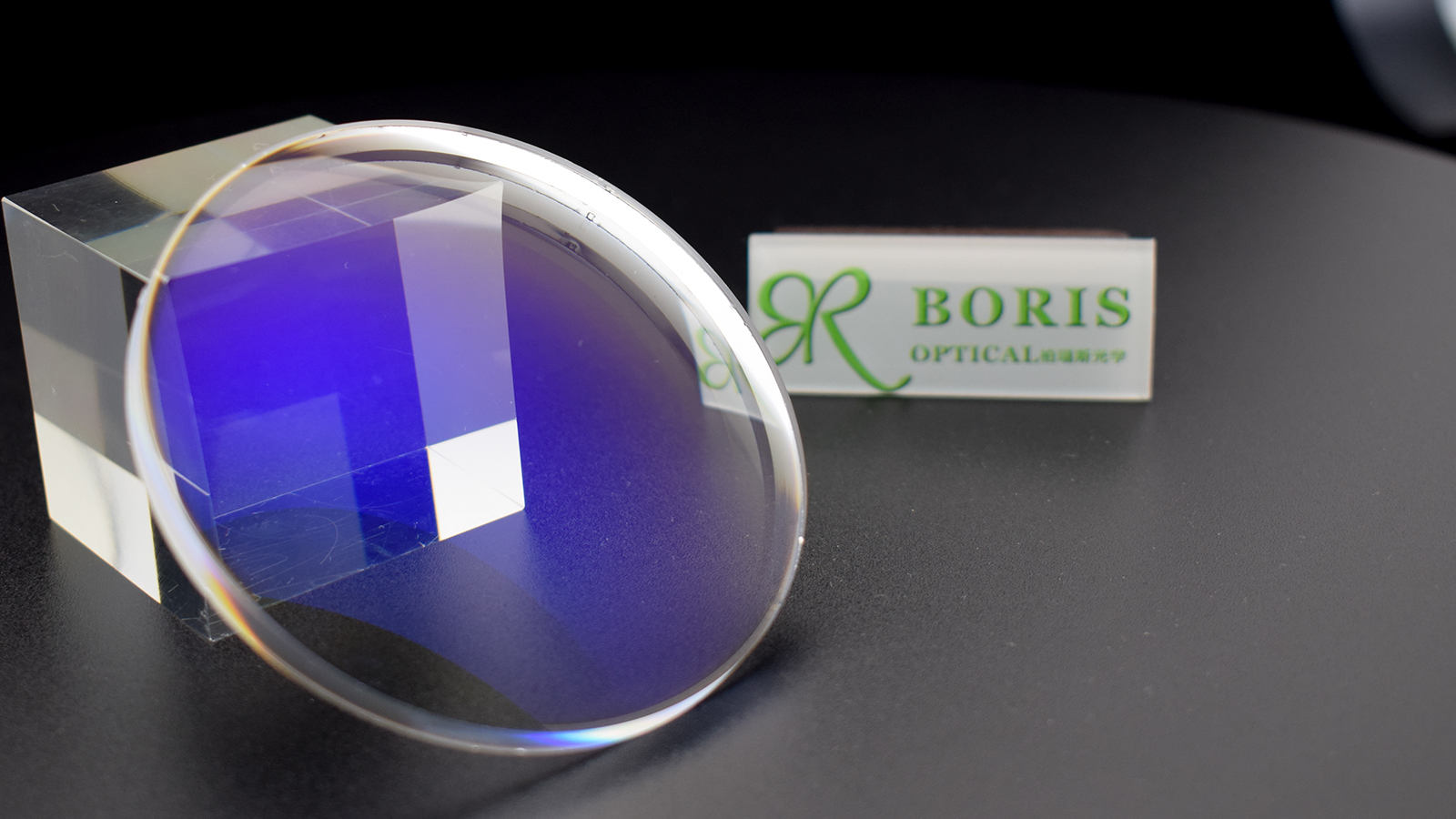

| Lenses Color: | White(indoor) | Coating Color: | Green/Blue |

| Index: | 1.61 | Specific Gravity: | 1.3 |

| Certification: | CE/ISO9001 | Abbe Value: | 41 |

| Diameter: | 75/70/65mm | Design: | Aspherical |

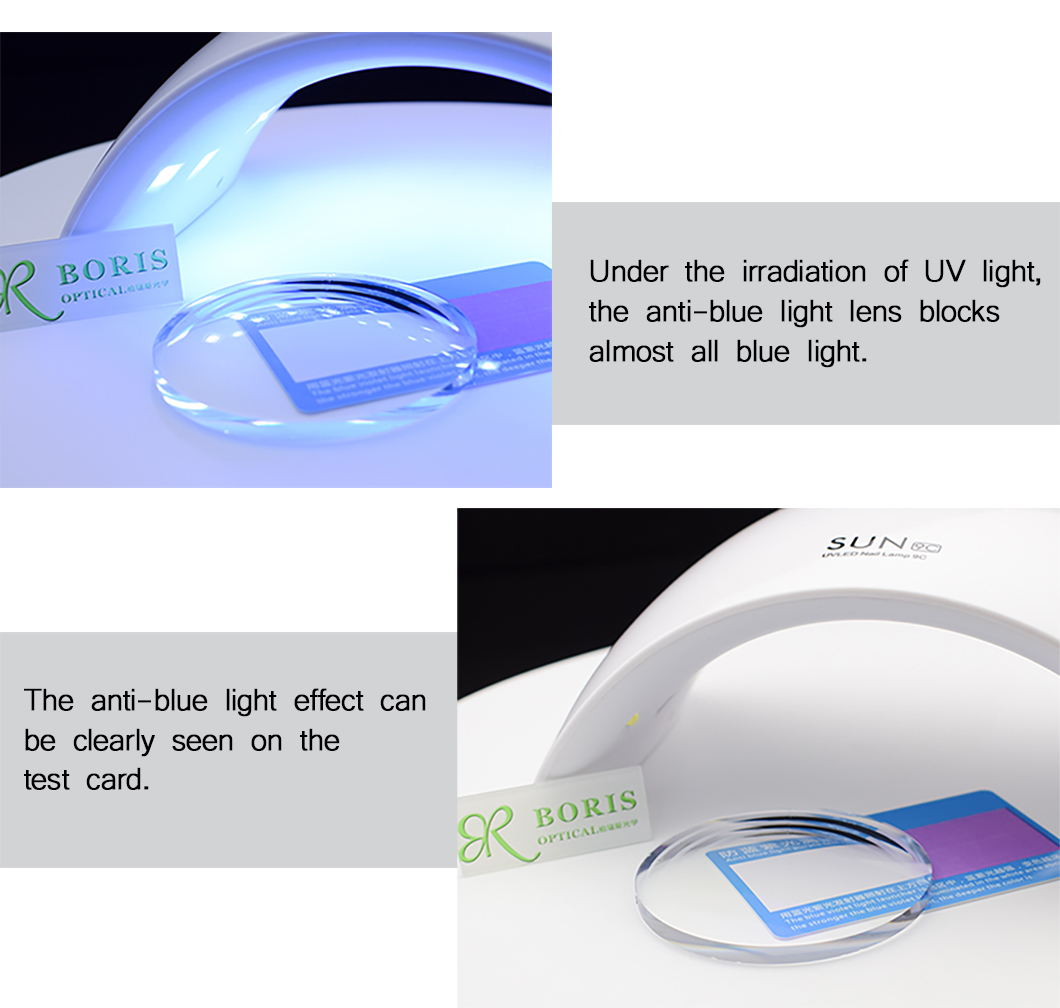

Anti-blue light glasses can effectively reduce the continuous damage of blue light to the eyes. Through the comparison and detection of portable spectrum analyzer, the use of anti-blue light glasses can effectively suppress the blue light intensity emitted by the mobile phone screen, and reduce the damage of harmful blue light to the eyes.

Anti-blue light glasses mainly through the lens surface coating will be harmful blue light reflection, or through the lens substrate added anti-blue light factor, harmful blue light absorption, so as to achieve the harmful blue light barrier, protect the eyes.

High myopia or super high myopia is recommended to choose lenses with a relatively high refractive index. It is recommended to choose lenses with a refractive index above 1.60. Higher refractive index lenses are usually more expensive due to differences in how they are made and the materials used.

Production Introduction

Aspherical lenses it curved surface is different from ordinary spherical lens, in pursuit of thin lens degree will need to change the lens surface, using spherical design, make the aberration and deformation increases, the results appear obvious image is not clear, horizon distortion, adverse phenomenon such as narrow field of vision, in the design of aspheric, fixed image, solve the problem of vision distortion and so on, at the same time, Make lenses lighter, thinner and flatter. Moreover, it still maintains excellent impact resistance, making the wearer safe to use.

MR-8 myopic lens is a kind of high-refractive index lens material with the most balanced performance index, and occupies the highest share in the lens material market with refractive index of 1.60. Suitable for the production of lenses of any degree, has become a new standard of lens materials. The MR-8 myopic lens can be used to make myopic glasses as well as hyperopic glasses. MR-8 material has a high degree of wear resistance, and a film layer is added on the surface of the lens to enhance the wear resistance effect, which is about 20% higher than that of ordinary lenses. High rigidity, high strength, strong impact resistance; Add special materials, good yellowing resistance; The aspherical design makes the lens image more clear and the field of view more broad.

Product Process